Selecting The Best Peristaltic Pump Tubing For Your Application

Are you searching for the perfect peristaltic pump tubing for your specific application? Look no further! In this comprehensive guide, we will explore the key factors to consider when selecting the best peristaltic pump tubing for your needs. Whether you are working in the medical, industrial, or research field, understanding the various tubing options available will help you make an informed decision and ensure optimal performance. Join us as we delve into the world of peristaltic pump tubing and discover how to choose the right one for your application.

- Understanding the Importance of Peristaltic Pump Tubing in Your Application

Peristaltic pump tubing plays a critical role in the performance and efficiency of peristaltic pumps in various applications. Understanding the importance of selecting the best peristaltic pump tubing for your specific application is essential to ensure optimal functionality and productivity. In this article, we will explore the key factors to consider when choosing peristaltic pump tubing, as well as the impact of using the right tubing on the overall system performance.

When it comes to selecting peristaltic pump tubing, there are several important considerations to take into account. The first factor to consider is the material of the tubing. Different materials offer varying levels of chemical compatibility, temperature resistance, and mechanical strength. It is crucial to assess the compatibility of the tubing material with the fluid being pumped, as well as the operating temperature range and the potential for abrasion or wear.

In addition to material compatibility, the size and dimensions of the tubing also play a significant role in the performance of the peristaltic pump. The inner diameter, wall thickness, and overall flexibility of the tubing can impact the flow rate, pressure capabilities, and pulsation characteristics of the pump. Choosing the right size and type of tubing for your application is essential to achieve the desired performance and efficiency.

Furthermore, the construction and design of the tubing can affect its longevity and durability in demanding applications. For instance, reinforced tubing with added strength and resilience may be necessary for high-pressure or abrasive pumping processes. It is important to evaluate the specific requirements of your application to determine the most suitable tubing construction for reliable and long-lasting performance.

Beyond the technical specifications, it is also important to consider the regulatory and quality standards that apply to the peristaltic pump tubing. Depending on the industry and application, there may be specific requirements for material certifications, chemical resistance, or environmental regulations. Ensuring compliance with these standards is essential to prevent potential safety risks and to maintain the integrity of the pumping system.

Choosing the best peristaltic pump tubing for your application is not only about meeting the technical requirements but also about optimizing the overall performance and efficiency of the pumping system. Using the right tubing can minimize downtime, reduce maintenance costs, and improve the reliability of the pump. It can also contribute to the quality and consistency of the end product in manufacturing and processing applications.

In conclusion, understanding the importance of peristaltic pump tubing in your application is crucial to achieving the desired performance and efficiency of the pumping system. By carefully evaluating the material compatibility, size and dimensions, construction, and regulatory requirements, you can select the best tubing that meets the specific needs of your application. Investing in high-quality and suitable peristaltic pump tubing can have a significant impact on the reliability, productivity, and overall success of your operations.

- Factors to Consider When Selecting Peristaltic Pump Tubing for Your Specific Needs

When it comes to selecting the best peristaltic pump tubing for your specific application, there are several key factors to consider. Peristaltic pumps are widely used in various industries, including pharmaceutical, food and beverage, and industrial manufacturing, and can be used for a wide range of applications such as dosing, transferring, and mixing. The right tubing is crucial to the performance and efficiency of the peristaltic pump, so it's important to carefully consider the following factors when making your selection.

Material Compatibility:

One of the most important factors to consider when selecting peristaltic pump tubing is the material compatibility with the fluid being pumped. Different fluids can have varying levels of compatibility with different materials, so it's important to choose tubing that is compatible with the specific fluid being used. For example, some fluids may be corrosive or abrasive, so it's important to select tubing that is resistant to these properties. Additionally, for applications where sterility is crucial, such as in pharmaceutical or biotech industries, it's important to choose tubing that is suitable for aseptic transfer.

Pressure and Temperature:

Another important factor to consider is the pressure and temperature requirements of the application. Different tubing materials have different pressure and temperature ratings, so it's important to select tubing that can withstand the specific conditions of the application. For example, high-pressure applications may require tubing with reinforced walls, while high-temperature applications may require tubing that is able to withstand elevated temperatures without degradation.

Flow Rate and Pump Speed:

The flow rate and pump speed of the peristaltic pump also need to be taken into consideration when selecting tubing. Different tubing materials have varying levels of flexibility and resistance, which can impact the flow rate and efficiency of the pump. It's important to select tubing that is able to maintain the desired flow rate at the pump speed being used. Additionally, the size and shape of the tubing can also impact the flow rate, so it's important to consider these factors as well.

Chemical Resistance:

In some applications, the fluid being pumped may contain aggressive chemicals or solvents. In these cases, it's crucial to select tubing that is resistant to chemical attack and degradation. Different tubing materials have varying levels of resistance to different chemicals, so it's important to select tubing that is able to withstand the specific chemical properties of the fluid being used.

Longevity and Cost:

Finally, the longevity and cost of the tubing should also be considered. While it's important to select tubing that is able to withstand the specific requirements of the application, it's also important to consider the cost and longevity of the tubing. Some tubing materials may have a higher initial cost but offer longer service life, while others may be more cost-effective but need to be replaced more frequently. It's important to weigh the cost and longevity of the tubing to ensure the best value for the specific application.

In conclusion, selecting the best peristaltic pump tubing for your specific application requires careful consideration of several key factors. Material compatibility, pressure and temperature requirements, flow rate and pump speed, chemical resistance, and longevity and cost are all important factors to consider when making your selection. By carefully considering these factors, you can ensure that you choose the best tubing for your specific needs and achieve optimal performance and efficiency from your peristaltic pump.

- Comparing Different Types of Peristaltic Pump Tubing Materials and Their Advantages

When it comes to selecting the best peristaltic pump tubing for your application, there are several factors to consider. One of the most important considerations is the type of material the tubing is made of. Different types of materials offer different advantages, so it's important to understand the characteristics of each and how they can benefit your specific application.

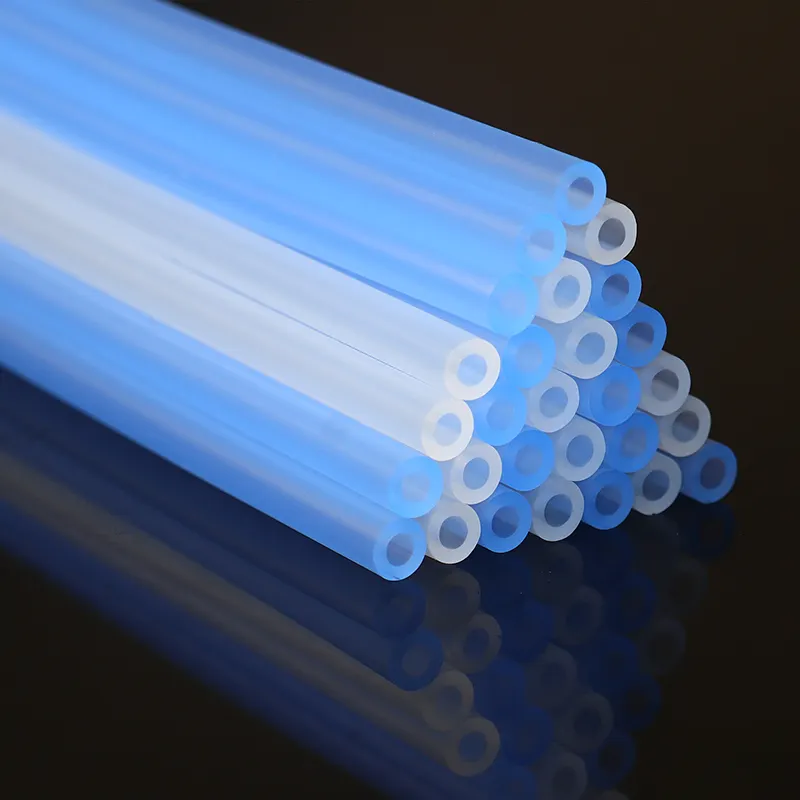

One of the most common materials used for peristaltic pump tubing is silicone. Silicone tubing is known for its flexibility and resistance to high temperatures, making it an excellent choice for applications that require flexibility and the ability to withstand heat. In addition, silicone tubing is also known for its biocompatibility, making it ideal for medical and pharmaceutical applications where the tubing comes into contact with sensitive materials.

Another popular material for peristaltic pump tubing is thermoplastic elastomer (TPE). TPE tubing is known for its durability and resistance to a wide range of chemicals, making it an excellent choice for applications that involve the pumping of aggressive or corrosive liquids. In addition, TPE tubing is also known for its flexibility and low extractables, making it a great choice for applications where purity is a concern.

In recent years, there has been increased interest in the use of fluoropolymer tubing for peristaltic pumps. Fluoropolymer tubing is known for its high chemical resistance, making it an excellent choice for applications that involve the pumping of harsh chemicals or solvents. In addition, fluoropolymer tubing is also known for its smooth surface, which reduces the risk of particle entrapment and makes it easier to clean and sterilize.

In addition to these materials, there are also other options available for peristaltic pump tubing, such as PVC, polyurethane, and natural rubber. Each of these materials offers its own set of advantages and disadvantages, so it's important to carefully consider the specific requirements of your application before making a decision.

When selecting the best peristaltic pump tubing for your application, it's important to consider not only the material of the tubing, but also other factors such as its inner diameter, wall thickness, and resilience to repeated compression. It's also important to consider the specific requirements of your application, such as the type of liquid being pumped, the temperature and pressure conditions, and any regulatory or safety standards that need to be met.

Overall, the selection of peristaltic pump tubing is a critical decision that can have a significant impact on the performance and safety of your application. By carefully considering the different types of materials available and their respective advantages, you can ensure that you select the best tubing for your specific needs and maximize the efficiency and reliability of your peristaltic pump system.

- Tips for Proper Installation and Maintenance of Peristaltic Pump Tubing

Peristaltic pumps are widely used in various industries such as pharmaceutical, food and beverage, and water treatment for their excellent pumping capabilities and hygiene advantages. However, to ensure the best performance of peristaltic pumps, proper installation and maintenance of peristaltic pump tubing are crucial. In this article, we will provide you with essential tips for selecting the best peristaltic pump tubing for your application, as well as guidelines for its proper installation and maintenance.

Selecting the right peristaltic pump tubing for your application is essential for ensuring optimal performance and longevity of the pump. There are several factors to consider when selecting peristaltic pump tubing, including the compatibility with the pumped fluid, the pump's speed and pressure requirements, and the tubing's chemical resistance and temperature capabilities.

Firstly, it is important to consider the compatibility of the tubing material with the pumped fluid. Different tubing materials such as silicone, PVC, and Tygon are available, each with its own chemical resistance and compatibility range. It is crucial to select a tubing material that is compatible with the specific fluid being pumped to avoid any material degradation or contamination.

Secondly, the pump's speed and pressure requirements should be taken into account when selecting peristaltic pump tubing. Different tubing materials and sizes have varying flow rates and pressure capabilities. It is important to choose tubing that can handle the required flow rate and pressure without causing any damage to the tubing or affecting the pump's performance.

Furthermore, considerations should be made for the tubing's chemical resistance and temperature capabilities. Some fluids may require tubing with high chemical resistance, while others may require tubing that can withstand high or low temperatures. It is crucial to select tubing that can endure the specific chemical and temperature conditions of the application to ensure the longevity of the tubing and the pump.

Once the appropriate peristaltic pump tubing has been selected, it is essential to ensure proper installation and maintenance for optimal pump performance. Proper installation of peristaltic pump tubing involves carefully following the manufacturer's guidelines for tubing loading and positioning. It is essential to ensure that the tubing is correctly loaded onto the pump's rollers and positioned to avoid any kinks or twists that may affect the pump's performance.

Regular maintenance of peristaltic pump tubing is also crucial for ensuring the pump's longevity and performance. This includes regular inspection of the tubing for any signs of wear or damage, as well as replacing the tubing at recommended intervals to prevent any potential failures. Additionally, proper cleaning and sterilization of the tubing are essential for applications requiring strict hygiene standards.

In conclusion, selecting the best peristaltic pump tubing for your application and ensuring its proper installation and maintenance are crucial for the optimal performance and longevity of peristaltic pumps. By considering factors such as compatibility with the pumped fluid, speed and pressure requirements, chemical resistance, and temperature capabilities when selecting tubing, and following manufacturer's guidelines for installation and maintenance, you can ensure the best performance of your peristaltic pump.

- Choosing the Right Peristaltic Pump Tubing Supplier for Quality and Reliability

When it comes to selecting the best peristaltic pump tubing for your application, it is essential to consider the quality and reliability of the supplier. Choosing the right peristaltic pump tubing supplier can make a significant difference in the performance and longevity of your equipment. With so many options available in the market, it can be challenging to determine the best supplier for your specific needs. In this article, we will discuss the key factors to consider when selecting a peristaltic pump tubing supplier to ensure that you are getting the best quality and reliability for your application.

Quality is a critical factor when choosing a peristaltic pump tubing supplier. The quality of the tubing directly impacts the performance and efficiency of the pump. It is essential to select a supplier that provides high-quality tubing that is durable, flexible, and resistant to corrosion and chemical damage. Look for a supplier that uses premium materials and employs strict quality control measures to ensure that the tubing meets industry standards and specifications.

Reliability is another crucial factor to consider when choosing a peristaltic pump tubing supplier. Reliability encompasses not only the quality of the tubing but also the consistency and dependability of the supplier in delivering products and providing support. A reliable supplier will have a proven track record of delivering high-quality products on time and will offer excellent customer service and technical support. Choose a supplier that has a solid reputation for reliability and is known for their commitment to customer satisfaction.

In addition to quality and reliability, it is essential to consider the range of products and services offered by the supplier. Look for a supplier that offers a wide variety of peristaltic pump tubing options to accommodate different applications and specifications. Whether you need tubing for pharmaceutical, food and beverage, laboratory, or industrial applications, a reputable supplier should have the expertise and resources to meet your specific requirements. Additionally, consider if the supplier offers value-added services such as custom fabrication, technical support, and after-sales service to enhance the overall experience of working with them.

Furthermore, it is important to consider the cost and overall value provided by the supplier. While price is a significant factor, it is essential to look beyond the initial cost and consider the long-term value of the products and services offered. A supplier that offers high-quality tubing at a competitive price and provides additional value in terms of support, expertise, and customization will ultimately result in cost savings and improved efficiency for your application.

Ultimately, selecting the right peristaltic pump tubing supplier for quality and reliability requires thorough research, careful consideration, and due diligence. Take the time to evaluate the reputation, experience, capabilities, and commitment of potential suppliers to ensure that you are making the best decision for your specific needs. By choosing a supplier that is dedicated to providing high-quality products, reliable service, and exceptional value, you can have confidence in the performance and longevity of your peristaltic pump system.

Conclusion

In conclusion, selecting the best peristaltic pump tubing for your application is crucial for ensuring optimal performance and efficiency. With our 12 years of experience in the industry, we understand the importance of choosing the right tubing to meet the specific needs of your application. By considering factors such as material compatibility, chemical resistance, and temperature tolerance, you can make an informed decision that will ultimately enhance the performance of your peristaltic pump. Our expertise and knowledge in this field make us well-equipped to assist you in selecting the best tubing for your application, so don't hesitate to reach out to us for guidance. Together, we can ensure that your peristaltic pump operates at its full potential.