The Advantages Of Using Peristaltic Hose Technology

Peristaltic hose technology is revolutionizing the way industries handle and transport fluids. With its numerous advantages and benefits, this cutting-edge technology offers an efficient and cost-effective solution for a wide range of applications. In this article, we will explore the many advantages of using peristaltic hose technology and how it can significantly improve your operations. Whether you are in the food and beverage, pharmaceutical, water treatment, or any other industry, understanding the benefits of peristaltic hose technology is crucial for staying ahead in today's competitive market. Keep reading to discover how this innovative technology can transform your business.

- Introduction to Peristaltic Hose Technology

Peristaltic hose technology is a cutting-edge method for transporting fluids in a wide range of industries. This innovative technology offers numerous advantages over traditional hose systems, making it an increasingly popular choice for businesses looking to improve efficiency, reduce maintenance costs, and ensure the safe and reliable transportation of liquids. In this article, we will provide a comprehensive introduction to peristaltic hose technology, exploring its key features, benefits, and applications.

At the heart of peristaltic hose technology is the use of a flexible hose that is squeezed and released in a pulsating manner to propel fluids through a system. This unique method of fluid transport offers several key advantages over conventional pumping systems. One of the primary benefits of peristaltic hose technology is its gentle, low-shear pumping action, which is ideal for transferring delicate or shear-sensitive fluids such as pharmaceuticals, chemicals, and food products. This can help to prevent degradation of the fluid, ensuring that it arrives at its destination in optimal condition.

Additionally, peristaltic hose technology is highly versatile and can be used to handle a wide range of viscosities, temperatures, and abrasive materials. This makes it an excellent choice for a variety of applications, from pharmaceutical manufacturing to wastewater treatment. The ability to handle such a diverse range of fluids makes peristaltic hose technology a cost-effective and flexible solution for many businesses.

Another key advantage of peristaltic hose technology is its ease of maintenance. Traditional pumping systems often require frequent maintenance and replacement of components, leading to costly downtime and production interruptions. In contrast, peristaltic hose technology is designed for simple maintenance and easy replacement of the hose, reducing the need for costly repairs and minimizing production disruptions.

In addition to these practical advantages, peristaltic hose technology also offers environmental benefits. The gentle pumping action of peristaltic hoses reduces the risk of leaks and spills, helping to minimize the environmental impact of fluid transportation. This can be particularly important for businesses operating in environmentally sensitive areas or industries with stringent environmental regulations.

Peristaltic hose technology has a wide range of applications across various industries. In the pharmaceutical and biotechnology sectors, peristaltic hose technology is widely used for the precise and gentle transfer of sensitive fluids, such as vaccines, cell cultures, and biopharmaceuticals. In the food and beverage industry, peristaltic hose technology is used for the safe and hygienic transportation of liquids, ensuring that products remain uncontaminated and of high quality. Additionally, peristaltic hose technology is commonly utilized in chemical processing, wastewater treatment, and mining operations, thanks to its ability to handle aggressive and abrasive materials with ease.

In conclusion, peristaltic hose technology offers numerous advantages over traditional pumping systems, making it a compelling choice for businesses seeking to improve efficiency, reduce maintenance costs, and ensure the safe and reliable transportation of fluids. With its gentle pumping action, versatility, ease of maintenance, and environmental benefits, peristaltic hose technology is a valuable asset for a wide range of industries. Whether it's handling delicate pharmaceuticals or abrasive chemicals, peristaltic hose technology provides a reliable and cost-effective solution for fluid transport needs.

- The Functionality and Design of Peristaltic Hose Technology

Peristaltic hose technology has revolutionized the way industries handle fluid transportation and pumping. This innovative technology offers a range of benefits, including superior functionality and design, which has made it an essential tool in various sectors such as pharmaceutical, food and beverage, wastewater treatment, and many others. In this article, we will delve into the advantages of using peristaltic hose technology, focusing specifically on its functionality and design.

In terms of functionality, peristaltic hose technology is unmatched in its ability to accurately and efficiently move fluids from one point to another. The unique mechanism of peristaltic pumps, which utilizes a rotating roller to compress and move the fluid through a flexible hose, ensures a consistent and gentle flow of the liquid, without any risk of contamination or backflow. This precise and steady pumping action makes peristaltic hose technology ideal for sensitive applications, where maintaining the purity and integrity of the fluid is paramount.

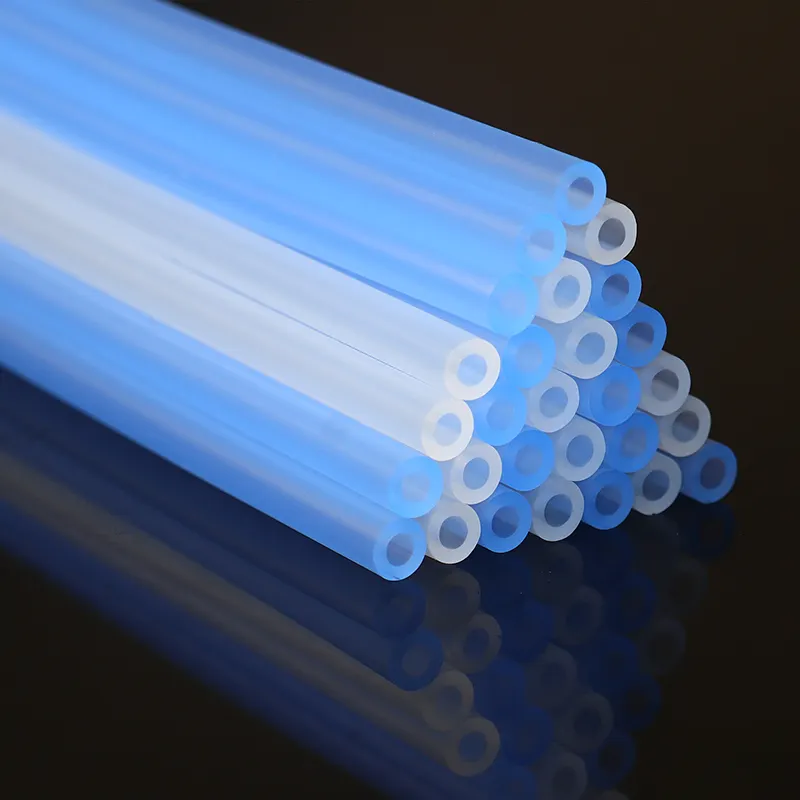

Furthermore, the design of peristaltic hose technology is well-suited for a wide range of industrial applications. The flexible tubing used in peristaltic pumps is available in various materials, such as silicone, EPDM, and natural rubber, allowing for compatibility with different types of fluids and chemicals. This versatility makes peristaltic hose technology a reliable choice for industries dealing with aggressive or abrasive fluids, as the tubing can be selected to withstand the specific requirements of the application.

Moreover, the simple and compact design of peristaltic pumps makes them easy to install and operate, requiring minimal maintenance and downtime. The absence of seals, valves, and diaphragms in peristaltic hose technology eliminates the need for regular replacement and reduces the risk of leaks or spills, resulting in cost savings and increased efficiency for businesses.

In addition to its practical functionality and design, peristaltic hose technology offers several other advantages that make it a preferred choice for fluid handling applications. One of the key benefits is the gentle pumping action of peristaltic pumps, which is particularly beneficial for shear-sensitive fluids, such as cell cultures and pharmaceutical products. The gentle squeezing action of the hose prevents foaming and degradation of the fluid, ensuring the integrity and quality of the product.

Furthermore, peristaltic hose technology is inherently hygienic and sanitary, as the fluid only comes into contact with the interior of the tubing, eliminating the risk of contamination from the pump itself. This feature is especially crucial in industries like food and beverage, pharmaceutical, and biotechnology, where maintaining a sterile environment is essential.

In conclusion, the functionality and design of peristaltic hose technology make it a highly effective and versatile solution for fluid handling and pumping. Its precise and gentle pumping action, coupled with its reliable and low-maintenance design, have made peristaltic hose technology an indispensable tool for a wide range of industries. Whether it is for pharmaceutical manufacturing, food processing, or wastewater treatment, peristaltic hose technology continues to offer unparalleled advantages, making it the preferred choice for fluid handling applications.

- Advantages of Using Peristaltic Hose Technology in Industrial Applications

Peristaltic hose technology is a highly efficient and reliable method used in various industrial applications. This innovative technology offers several advantages over traditional hose systems, making it an ideal choice for industries such as pharmaceutical, food and beverage, and wastewater treatment. In this article, we will explore the numerous benefits of using peristaltic hose technology in industrial applications.

One of the primary advantages of peristaltic hose technology is its ability to handle a wide range of fluids and substances with ease. The flexible nature of the hose allows it to accommodate different materials without the risk of cross-contamination. This is particularly important in industries where maintaining the purity of fluids is crucial, such as in pharmaceutical and food processing plants. Peristaltic hoses are designed to handle both corrosive and abrasive fluids, making them a versatile option for various industrial applications.

Another key advantage of peristaltic hose technology is its ability to provide accurate and consistent flow rates. The design of the hose prevents fluid from coming into contact with any internal components, reducing the risk of clogging or flow disruptions. This precise control over flow rates is essential in industries where dosing and metering of fluids are critical, such as in chemical manufacturing and water treatment facilities. With peristaltic hose technology, industrial processes can be more efficient and reliable, resulting in improved overall production quality.

Additionally, peristaltic hose technology offers easy maintenance and minimal downtime. The hose is the only component that comes into contact with the fluid, making it the only part that requires regular replacement. This simplifies maintenance and reduces the need for frequent cleaning and sterilization of other components, saving both time and labor costs. As a result, industrial operations can run smoothly with minimal disruptions, improving overall productivity.

Furthermore, peristaltic hose technology is known for its gentle fluid handling capabilities. The squeezing action of the hose prevents shear forces and air entrapment, which can be harmful to delicate fluids. This is particularly beneficial in industries where sensitive materials, such as biological samples or expensive chemicals, are being transferred. The gentle handling of fluids helps maintain their integrity and quality, ensuring consistent and reliable results in industrial processes.

In conclusion, the advantages of using peristaltic hose technology in industrial applications are numerous and significant. Its ability to handle a wide range of fluids, provide accurate flow rates, offer easy maintenance, and gentle fluid handling makes it an ideal choice for various industries. With its versatility, reliability, and efficiency, peristaltic hose technology is a valuable asset in improving the overall performance of industrial processes. As industries continue to evolve and demand more advanced fluid handling solutions, peristaltic hose technology is sure to play a crucial role in meeting these needs.

- Environmental and Safety Benefits of Using Peristaltic Hose Technology

Peristaltic hose technology is a revolutionary innovation that is transforming the way industries handle fluid transfer and pumping systems. This article will explore the environmental and safety benefits of using peristaltic hose technology, highlighting its advantages over traditional pumping methods and its potential to improve operations across various industries.

Environmental Benefits of Peristaltic Hose Technology

One of the key environmental benefits of peristaltic hose technology is its ability to reduce the risk of fluid leakage and spills. Unlike traditional pumping systems, which often rely on seals and valves that can degrade over time, peristaltic hoses have a simple, closed-loop design that minimizes the risk of leaks and spills. This can help companies reduce their environmental impact by preventing contamination of soil and water sources, as well as minimizing the need for clean-up operations and regulatory fines.

In addition, peristaltic hose technology is also more energy-efficient than traditional pumping methods. The design of the hoses allows for precise control over fluid flow, reducing the amount of energy required to pump fluids through a system. This not only helps companies reduce their carbon footprint, but also lowers operating costs and improves overall environmental sustainability.

Safety Benefits of Peristaltic Hose Technology

From a safety perspective, peristaltic hose technology offers significant advantages over traditional pumping systems. The closed-loop design of the hoses minimizes the risk of exposure to hazardous chemicals and fluids, reducing the potential for accidents and injuries in the workplace. This is especially important in industries where workers are routinely exposed to dangerous substances, such as pharmaceutical manufacturing and chemical processing.

Furthermore, peristaltic hoses are designed to handle a wide range of fluids, including abrasive and corrosive substances, without the need for additional containment measures. This reduces the need for special handling procedures and equipment, simplifying operations and improving overall safety in the workplace.

Practical Applications of Peristaltic Hose Technology

Peristaltic hose technology has a wide range of practical applications across various industries, including pharmaceuticals, food and beverage, mining, water treatment, and chemical processing. In the pharmaceutical industry, for example, peristaltic hoses are used to transfer sensitive and valuable fluids, such as active pharmaceutical ingredients (APIs), with minimal risk of contamination. This helps companies maintain high standards of product integrity and safety while reducing the risk of costly product recalls.

In the food and beverage industry, peristaltic hose technology is used for precision metering and blending of ingredients, as well as handling delicate fluids that require gentle pumping actions. This ensures consistent product quality and reduces the risk of product spoilage, enhancing food safety and customer satisfaction.

In conclusion, peristaltic hose technology offers significant environmental and safety benefits over traditional pumping methods, making it an attractive option for companies looking to improve their operations while minimizing their impact on the environment. With its energy-efficient design, minimal risk of leaks and spills, and enhanced safety features, peristaltic hose technology is poised to revolutionize the way industries handle fluid transfer and pumping systems.

- The Future of Peristaltic Hose Technology and its Potential Applications in Various Industries

Peristaltic hose technology has been a game changer in various industries for its unique design and functions. This article will delve into the future of peristaltic hose technology and its potential applications in numerous industries.

What is Peristaltic Hose Technology?

Peristaltic hose technology is a type of positive displacement pump used for pumping a variety of fluids. This technology works on the principle of peristalsis, where a flexible tube is squeezed along its length by a rotor, thus pushing the fluid inside the tube. The mechanism of peristaltic hose technology differs from traditional pumps as it does not require any seals, valves, or other parts that come into direct contact with the fluid, making it a hygienic and low maintenance choice.

Future of Peristaltic Hose Technology:

The future of peristaltic hose technology looks promising with continuous advancements and innovations in the field. As technology improves, peristaltic hoses are becoming more efficient, durable, and versatile, which opens up a multitude of potential applications in various industries.

Potential Applications in Various Industries:

1. Medical and Pharmaceutical Industry:

Peristaltic hose technology has already made significant contributions to the medical and pharmaceutical industry as a reliable and precise method of fluid transfer. The technology is widely used in drug delivery systems, dialysis machines, and other medical equipment where accurate and sterile fluid transfer is critical.

2. Food and Beverage Industry:

The food and beverage industry can benefit from peristaltic hose technology due to its hygienic design and ability to handle delicate fluids. This technology is commonly used for transferring ingredients, flavorings, and other fluids in food and beverage production processes.

3. Chemical and Manufacturing Industry:

Peristaltic hose technology can also be applied in the chemical and manufacturing industry for the transfer of corrosive, abrasive, or sensitive fluids. With the ability to handle a wide range of chemicals and maintain a contamination-free environment, peristaltic hoses are an ideal choice for various industrial processes.

4. Water and Waste Management:

In the field of water and waste management, peristaltic hose technology can be used for dosing and transferring various chemicals and fluids in water treatment plants, wastewater management facilities, and other related applications. The gentle pumping action of peristaltic hoses also makes them suitable for handling shear-sensitive fluids.

As peristaltic hose technology continues to evolve and improve, its potential applications in various industries will expand even further. The advantages of using peristaltic hose technology, such as its hygienic design, precise fluid transfer, and versatility, make it an attractive option for numerous industrial applications. With ongoing research and advancements, peristaltic hose technology is set to revolutionize fluid transfer processes across a wide range of industries.

Conclusion

In conclusion, the advantages of using peristaltic hose technology are truly impressive. From its ability to handle a wide range of fluids and materials to its low maintenance requirements and long service life, it's clear that this technology offers numerous benefits for various industries. As a company with 12 years of experience in the industry, we have seen firsthand the positive impact that peristaltic hose technology can have on operations, efficiency, and overall performance. With its reliability and versatility, it's no wonder that more and more companies are turning to peristaltic hose technology to meet their fluid handling needs. If you're looking to optimize your operations and improve your bottom line, consider incorporating peristaltic hose technology into your processes.