Understanding The Benefits Of Peristaltic Tubing In Industrial Applications

Are you curious about the benefits of peristaltic tubing in industrial applications? Look no further! In this article, we will delve into the numerous advantages of using peristaltic tubing in industrial settings. From its ability to maintain product integrity to its resistance to abrasion and corrosion, there are countless reasons why peristaltic tubing is the ideal choice for a wide range of industrial processes. Keep reading to learn more about how this innovative tubing solution can enhance efficiency and performance in your industrial operations.

- Introduction to Peristaltic Tubing in Industrial Applications

to Peristaltic Tubing in Industrial Applications

Peristaltic tubing plays a crucial role in various industrial applications, offering a wide range of benefits and advantages over other types of tubing. In this article, we will explore the importance of peristaltic tubing in industrial settings and discuss its numerous benefits for different applications. From pharmaceuticals to food and beverage production, peristaltic tubing has become an essential component in the manufacturing process.

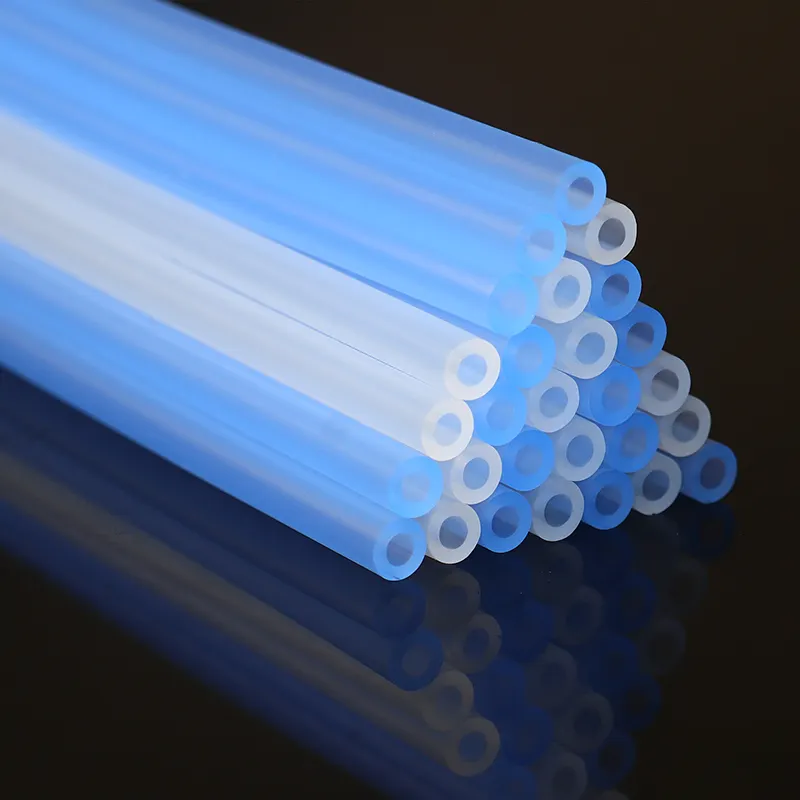

First, it is important to understand what peristaltic tubing is and how it functions. Peristaltic tubing is designed with a unique construction that allows for the consistent movement of fluids through the tubing. This is achieved through a series of rollers that compress and release the tubing, creating a pumping action that propels the fluid through the tubing. This design ensures a continuous flow of liquids without the risk of contamination or leakage, making it ideal for a wide range of industrial applications.

One of the key benefits of peristaltic tubing is its ability to handle a variety of fluids, including corrosive and abrasive materials. This makes it an excellent choice for industries that deal with harsh chemicals, such as the pharmaceutical and chemical manufacturing sectors. The resilience of peristaltic tubing also means that it can withstand high pressures and temperatures, making it a reliable choice for demanding industrial processes.

In addition to its durability, peristaltic tubing offers the advantage of being easy to clean and maintain. Its smooth, flexible surface prevents the build-up of particles and other contaminants, reducing the risk of cross-contamination and ensuring the purity of the transported fluids. This is particularly important in industries such as food and beverage production, where hygiene and product integrity are of the utmost importance.

Furthermore, peristaltic tubing provides a cost-effective solution for industrial applications. Its long lifespan and minimal maintenance requirements result in lower operating costs, making it a practical choice for businesses looking to optimize their production processes. Additionally, the precision and accuracy of peristaltic tubing make it an efficient option for dosing and metering applications, contributing to improved productivity and resource utilization.

Peristaltic tubing also offers the advantage of flexibility and adaptability. Its versatile design allows for easy integration into existing systems, providing a seamless solution for a wide range of industrial processes. Whether it is used for fluid transfer, sampling, or filtration, peristaltic tubing can be customized to meet specific requirements, making it a versatile and reliable choice for industrial applications.

In conclusion, peristaltic tubing plays a crucial role in industrial applications, offering numerous benefits and advantages for a wide range of industries. Its durability, flexibility, and cost-effectiveness make it a valuable component in the manufacturing process, contributing to improved efficiency, reliability, and product quality. As industries continue to evolve and demand increasingly specialized solutions, the importance of peristaltic tubing in industrial applications is expected to grow, driving innovation and advancements in manufacturing technology.

- Advantages of Peristaltic Tubing in Industrial Settings

Peristaltic tubing is a crucial component in many industrial applications, offering a wide range of advantages that make it a preferred choice for various processes. From pharmaceutical and biotechnology to food and beverage production, peristaltic tubing has become an indispensable tool in ensuring smooth and efficient operations. In this article, we will delve into the numerous benefits of peristaltic tubing in industrial settings and understand why it is considered a valuable asset in different industries.

One of the primary advantages of peristaltic tubing in industrial settings is its exceptional flexibility and durability. The unique design of peristaltic tubing allows it to withstand a wide range of temperatures, pressures, and chemical exposures, making it suitable for a variety of applications. This flexibility and resilience make peristaltic tubing an ideal choice for industries that require reliable and long-lasting equipment to support their operations.

Furthermore, peristaltic tubing offers excellent fluid compatibility, making it suitable for use with a wide range of substances, including corrosive chemicals, abrasive materials, and sensitive biological compounds. This versatility allows for seamless integration into different industrial processes, providing a consistent and reliable means of transporting and controlling fluids.

In addition to its compatibility with various substances, peristaltic tubing also offers hygienic benefits, particularly in industries such as pharmaceuticals and food and beverage production. The design of peristaltic tubing minimizes the risk of cross-contamination, making it an ideal choice for applications that require a high level of cleanliness and sterility. This is essential in ensuring product integrity and meeting stringent regulatory requirements in these industries.

Moreover, peristaltic tubing provides precise and accurate fluid control, making it an invaluable tool in industrial settings where precision is critical. The peristaltic action of the tubing ensures a consistent flow rate and eliminates the need for complex and expensive flow control mechanisms, simplifying processes and reducing operational costs.

Another significant advantage of peristaltic tubing is its low maintenance requirements. The simple design of peristaltic pumps and the tubing itself minimizes the need for frequent repairs and replacements, reducing downtime and associated costs. This reliability and ease of maintenance make peristaltic tubing an attractive option for industries looking to streamline their operations and minimize equipment-related disruptions.

Furthermore, peristaltic tubing is environmentally friendly, as it does not require the use of seals, valves, or lubricants that can potentially leak or contaminate the surrounding environment. This reduces the risk of environmental harm and ensures compliance with stringent environmental regulations, making peristaltic tubing a sustainable choice for industrial applications.

In conclusion, peristaltic tubing offers a multitude of advantages in industrial settings, ranging from its flexibility and durability to its hygienic benefits and precise fluid control. Its compatibility with a wide range of substances, low maintenance requirements, and environmental friendliness further enhance its appeal as a valuable asset in various industries. As technology continues to advance, the versatility and reliability of peristaltic tubing make it an essential tool for ensuring smooth and efficient industrial processes.

- Applications of Peristaltic Tubing in Various Industries

Peristaltic tubing is a versatile and efficient material that has found widespread applications across various industries. Its unique properties make it an ideal choice for a wide range of industrial processes, offering numerous benefits over traditional tubing materials. In this article, we will explore the diverse applications of peristaltic tubing in different industries and understand the reasons behind its growing popularity.

In the pharmaceutical industry, peristaltic tubing plays a crucial role in the manufacturing of medications and vaccines. Its sterile and non-reactive nature makes it the preferred choice for transferring sensitive and potent drugs without the risk of contamination or degradation. The precise and consistent flow of fluids through peristaltic tubing ensures accurate dosing and superior product quality, meeting the stringent requirements of the pharmaceutical sector.

The food and beverage industry also relies on peristaltic tubing for various applications, such as transferring liquid ingredients, flavorings, and additives. The hygienic properties of peristaltic tubing make it suitable for handling consumable products, ensuring that there is no risk of leaching or contamination. Additionally, its gentle pumping action helps to maintain the integrity of delicate food products, making it an indispensable component in food processing and packaging operations.

Moreover, in the biotechnology and research sector, peristaltic tubing is employed for a wide range of applications, including cell culture, fermentation, and chromatography. Its ability to handle sensitive biological materials and maintain aseptic conditions makes it an essential component in bioprocessing and laboratory settings. The flexibility and compatibility of peristaltic tubing with a variety of chemicals and solvents make it a valuable asset for scientists and researchers working with diverse substances.

In the industrial manufacturing and production domain, peristaltic tubing finds applications in conveying abrasive fluids, corrosive chemicals, and viscous materials. Its robust and abrasion-resistant construction allows it to withstand the challenges posed by harsh industrial environments, ensuring reliable and long-lasting performance. The flexibility of peristaltic tubing also enables it to be easily integrated into existing equipment and systems, providing a cost-effective solution for fluid transfer and process automation.

Furthermore, the renewable energy sector leverages peristaltic tubing for applications related to biofuel production, wastewater treatment, and renewable energy generation. Its ability to handle organic materials and endure demanding operating conditions makes it a suitable choice for sustainable energy initiatives. The efficiency and reliability of peristaltic tubing contribute to the advancement of renewable energy technologies, driving progress towards a greener and more sustainable future.

In conclusion, the applications of peristaltic tubing in various industries are diverse and far-reaching, encompassing pharmaceuticals, food and beverage, biotechnology, industrial manufacturing, and renewable energy. Its unique combination of hygienic, versatile, and durable properties makes it an indispensable component in a wide range of industrial processes, contributing to enhanced productivity, product quality, and operational efficiency. As industries continue to evolve and innovate, peristaltic tubing will undoubtedly remain a critical and valuable resource for meeting the fluid transfer needs of diverse applications.

- Factors to Consider When Choosing Peristaltic Tubing for Industrial Use

Peristaltic tubing is a crucial component in many industrial applications, including pharmaceutical production, food processing, and chemical manufacturing. When choosing peristaltic tubing for industrial use, there are several factors that must be considered to ensure optimal performance and efficiency. In this article, we will explore the benefits of peristaltic tubing in industrial applications and discuss the key factors that should be taken into account when selecting the right tubing for specific industrial needs.

One of the primary benefits of peristaltic tubing in industrial applications is its ability to provide precise and accurate fluid transfer. Peristaltic pumps use a rotating roller mechanism to compress and release the tubing, creating a positive displacement action that effectively moves fluids without the risk of contamination or leakage. This makes peristaltic tubing an ideal choice for applications where precise control of fluid flow is necessary, such as in pharmaceutical manufacturing where accurate dosing is critical.

Another advantage of peristaltic tubing is its compatibility with a wide range of fluids, including abrasive and corrosive substances. The material composition of the tubing plays a crucial role in determining its resistance to specific chemicals and environmental conditions. When selecting peristaltic tubing for industrial use, it is essential to consider the chemical compatibility of the tubing material with the substances it will come into contact with during operation. This will help prevent degradation of the tubing and ensure long-term reliability in harsh industrial environments.

Furthermore, the durability and strength of the peristaltic tubing are important factors to consider when choosing tubing for industrial applications. Industrial processes often involve high pressures and repetitive movements, which can put significant stress on the tubing. Selecting tubing with a robust construction and excellent tensile strength will help prevent premature wear and tear, ultimately reducing the risk of costly downtime and maintenance.

In addition to material compatibility and durability, the size and dimensions of the peristaltic tubing also play a critical role in its suitability for industrial use. The tubing must be able to accommodate the required flow rates and pressures of the specific application, without restricting fluid movement or causing excessive back pressure. It is essential to carefully consider the inner diameter, wall thickness, and overall flexibility of the tubing to ensure it meets the performance requirements of the industrial process.

Moreover, one cannot overlook the importance of regulatory compliance and certifications when choosing peristaltic tubing for industrial use, especially in industries such as pharmaceuticals and food processing. Certified tubing that meets industry standards for cleanliness, purity, and safety can help ensure compliance with regulatory requirements and maintain the integrity of the final product.

In conclusion, peristaltic tubing offers numerous benefits for industrial applications, including precise fluid transfer, chemical compatibility, and durability. When choosing peristaltic tubing for industrial use, it is essential to consider factors such as material compatibility, durability, dimensions, and regulatory compliance to ensure optimal performance and reliability. By carefully evaluating these factors, industrial operators can select the right peristaltic tubing to meet the specific needs of their applications and achieve efficient and cost-effective fluid transfer.

- Case Studies Highlighting the Success of Peristaltic Tubing in Industrial Environments

Peristaltic tubing has emerged as a crucial component in industrial environments, offering a range of benefits that have proven to be highly effective in various applications. This article aims to provide a comprehensive understanding of the advantages of peristaltic tubing in industrial settings, with a specific focus on case studies that highlight its success.

One of the key benefits of peristaltic tubing is its ability to handle a wide range of fluids and chemicals with ease. This makes it a versatile choice for industries such as pharmaceuticals, food and beverage, and chemical manufacturing, where the handling of different types of fluids is a crucial aspect of the production process. Case studies have shown that peristaltic tubing is able to withstand the corrosive and abrasive nature of many chemicals, making it an ideal choice for these industries.

Furthermore, peristaltic tubing is known for its exceptional hygiene and cleanliness, making it a preferred option in industries where sanitation and sterility are of utmost importance. This is particularly evident in pharmaceutical and biotechnology companies, where the risk of contamination can have severe consequences. The use of peristaltic tubing has been found to significantly reduce the risk of contamination, ensuring the integrity of the final products.

In addition to its chemical resistance and hygienic properties, peristaltic tubing is also valued for its ease of maintenance and long-term durability. Case studies have demonstrated that companies using peristaltic tubing have experienced minimal downtime and reduced maintenance costs, resulting in increased productivity and cost savings over time. This has made peristaltic tubing a valuable investment for many industrial businesses.

Another key advantage of peristaltic tubing is its ability to provide precise and consistent flow rates, which is crucial in industries such as pharmaceutical manufacturing and laboratory research. The controlled and uniform flow of fluids through peristaltic tubing has been shown to improve the accuracy and reliability of various processes, leading to higher quality products and increased efficiency.

Moreover, peristaltic tubing offers a non-contaminating pumping action, making it suitable for sensitive applications where maintaining the purity of the product is essential. For example, in the production of high-purity chemicals and pharmaceuticals, peristaltic tubing has proven to be a reliable solution for ensuring product integrity.

In conclusion, the success of peristaltic tubing in industrial environments is evident through the numerous case studies that highlight its advantages. From its chemical resistance and hygienic properties to its ease of maintenance and precise flow control, peristaltic tubing has become an essential component in a wide range of industrial applications. As the demand for high-performing and reliable tubing solutions continues to grow, peristaltic tubing is expected to play an increasingly important role in shaping the future of industrial manufacturing.

Conclusion

In conclusion, it is clear that peristaltic tubing offers a wide range of benefits in industrial applications. From its ability to handle a variety of fluids and materials to its durability and ease of maintenance, the advantages of using peristaltic tubing are numerous. As a company with 12 years of experience in the industry, we have seen firsthand the positive impact that peristaltic tubing can have on industrial processes. We are confident that by incorporating peristaltic tubing into your operations, you can improve efficiency, reduce downtime, and ultimately enhance the overall performance of your industrial applications. We are committed to providing the highest quality peristaltic tubing to our customers and are dedicated to helping you harness the full potential of this versatile and reliable solution. Trust in the benefits of peristaltic tubing and experience the difference it can make in your industrial operations.