एक सिलिकॉन ट्यूब निर्माता और कारखाना जो 14 वर्षों से सटीक कस्टम सिलिकॉन उत्पादों के उत्पादन के लिए समर्पित है।

पेरिस्टाल्टिक होज़ तकनीक के उपयोग के लाभ

पेरिस्टाल्टिक होज़ तकनीक उद्योगों में तरल पदार्थों के प्रबंधन और परिवहन के तरीके में क्रांतिकारी बदलाव ला रही है। इसके अनेक लाभों और फायदों के साथ, यह अत्याधुनिक तकनीक विभिन्न प्रकार के अनुप्रयोगों के लिए एक कुशल और लागत प्रभावी समाधान प्रदान करती है। इस लेख में, हम पेरिस्टाल्टिक होज़ तकनीक के उपयोग के कई फायदों और यह आपके संचालन को किस प्रकार बेहतर बना सकती है, इस पर चर्चा करेंगे। चाहे आप खाद्य एवं पेय पदार्थ, दवा, जल उपचार या किसी अन्य उद्योग में हों, आज के प्रतिस्पर्धी बाज़ार में आगे रहने के लिए पेरिस्टाल्टिक होज़ तकनीक के लाभों को समझना अत्यंत महत्वपूर्ण है। यह जानने के लिए पढ़ते रहें कि यह नवोन्मेषी तकनीक आपके व्यवसाय को कैसे बदल सकती है।

- पेरिस्टाल्टिक होज़ प्रौद्योगिकी का परिचय

पेरिस्टाल्टिक होज़ तकनीक विभिन्न उद्योगों में तरल पदार्थों के परिवहन की एक अत्याधुनिक विधि है। यह नवोन्मेषी तकनीक पारंपरिक होज़ प्रणालियों की तुलना में अनेक लाभ प्रदान करती है, जिसके कारण यह उन व्यवसायों के लिए एक लोकप्रिय विकल्प बन रही है जो दक्षता में सुधार, रखरखाव लागत में कमी और तरल पदार्थों के सुरक्षित एवं विश्वसनीय परिवहन को सुनिश्चित करना चाहते हैं। इस लेख में, हम पेरिस्टाल्टिक होज़ तकनीक का विस्तृत परिचय देंगे, जिसमें इसकी प्रमुख विशेषताओं, लाभों और अनुप्रयोगों का विश्लेषण किया जाएगा।

पेरिस्टाल्टिक होज़ तकनीक का मूल सिद्धांत एक लचीली नली का उपयोग है जिसे स्पंदित तरीके से दबाकर और छोड़कर तरल पदार्थों को एक प्रणाली के माध्यम से प्रवाहित किया जाता है। तरल परिवहन की यह अनूठी विधि पारंपरिक पंपिंग प्रणालियों की तुलना में कई महत्वपूर्ण लाभ प्रदान करती है। पेरिस्टाल्टिक होज़ तकनीक का एक प्रमुख लाभ इसकी कोमल, कम-शियर वाली पंपिंग क्रिया है, जो फार्मास्यूटिकल्स, रसायन और खाद्य उत्पादों जैसे नाजुक या शियर-संवेदनशील तरल पदार्थों के स्थानांतरण के लिए आदर्श है। यह तरल पदार्थ के क्षरण को रोकने में मदद कर सकता है, जिससे यह सुनिश्चित होता है कि यह अपने गंतव्य तक सर्वोत्तम स्थिति में पहुंचे।

इसके अतिरिक्त, पेरिस्टाल्टिक होज़ तकनीक अत्यधिक बहुमुखी है और इसका उपयोग विभिन्न प्रकार की श्यानता, तापमान और घर्षणकारी पदार्थों को संभालने के लिए किया जा सकता है। यह इसे फार्मास्युटिकल निर्माण से लेकर अपशिष्ट जल उपचार तक, कई अनुप्रयोगों के लिए एक उत्कृष्ट विकल्प बनाता है। इतने विविध प्रकार के तरल पदार्थों को संभालने की क्षमता पेरिस्टाल्टिक होज़ तकनीक को कई व्यवसायों के लिए लागत प्रभावी और लचीला समाधान बनाती है।

पेरिस्टाल्टिक होज़ तकनीक का एक और प्रमुख लाभ इसकी आसान रखरखाव क्षमता है। पारंपरिक पंपिंग प्रणालियों में अक्सर बार-बार रखरखाव और पुर्जों को बदलने की आवश्यकता होती है, जिससे लागत में भारी नुकसान होता है और उत्पादन बाधित होता है। इसके विपरीत, पेरिस्टाल्टिक होज़ तकनीक को सरल रखरखाव और होज़ को आसानी से बदलने के लिए डिज़ाइन किया गया है, जिससे महंगे मरम्मत कार्यों की आवश्यकता कम हो जाती है और उत्पादन में होने वाली बाधाएँ न्यूनतम हो जाती हैं।

इन व्यावहारिक लाभों के अलावा, पेरिस्टाल्टिक होज़ तकनीक पर्यावरणीय लाभ भी प्रदान करती है। पेरिस्टाल्टिक होज़ की धीमी पंपिंग क्रिया रिसाव और फैलाव के जोखिम को कम करती है, जिससे तरल पदार्थों के परिवहन के पर्यावरणीय प्रभाव को कम करने में मदद मिलती है। यह उन व्यवसायों के लिए विशेष रूप से महत्वपूर्ण हो सकता है जो पर्यावरण की दृष्टि से संवेदनशील क्षेत्रों में काम करते हैं या उन उद्योगों के लिए जहां पर्यावरण संबंधी कड़े नियम लागू होते हैं।

पेरिस्टाल्टिक होज़ तकनीक का उपयोग विभिन्न उद्योगों में व्यापक रूप से होता है। फार्मास्युटिकल और जैव प्रौद्योगिकी क्षेत्रों में, संवेदनशील तरल पदार्थों, जैसे टीके, सेल कल्चर और जैव-औषधीय पदार्थों के सटीक और सुरक्षित स्थानांतरण के लिए पेरिस्टाल्टिक होज़ तकनीक का व्यापक रूप से उपयोग किया जाता है। खाद्य और पेय उद्योग में, तरल पदार्थों के सुरक्षित और स्वच्छ परिवहन के लिए पेरिस्टाल्टिक होज़ तकनीक का उपयोग किया जाता है, जिससे उत्पादों की गुणवत्ता सुनिश्चित होती है और वे संदूषण मुक्त रहते हैं। इसके अतिरिक्त, आक्रामक और घर्षणकारी पदार्थों को आसानी से संभालने की क्षमता के कारण, पेरिस्टाल्टिक होज़ तकनीक का उपयोग रासायनिक प्रसंस्करण, अपशिष्ट जल उपचार और खनन कार्यों में भी किया जाता है।

निष्कर्षतः, पेरिस्टाल्टिक होज़ तकनीक पारंपरिक पंपिंग प्रणालियों की तुलना में अनेक लाभ प्रदान करती है, जिससे यह उन व्यवसायों के लिए एक आकर्षक विकल्प बन जाती है जो दक्षता में सुधार, रखरखाव लागत में कमी और तरल पदार्थों के सुरक्षित एवं विश्वसनीय परिवहन को सुनिश्चित करना चाहते हैं। अपनी कोमल पंपिंग क्रिया, बहुमुखी प्रतिभा, रखरखाव में आसानी और पर्यावरणीय लाभों के कारण, पेरिस्टाल्टिक होज़ तकनीक विभिन्न उद्योगों के लिए एक मूल्यवान संसाधन है। चाहे नाज़ुक औषधियों का परिवहन हो या अपघर्षक रसायनों का, पेरिस्टाल्टिक होज़ तकनीक तरल पदार्थों के परिवहन की आवश्यकताओं के लिए एक विश्वसनीय और लागत प्रभावी समाधान प्रदान करती है।

- पेरिस्टाल्टिक होज़ प्रौद्योगिकी की कार्यक्षमता और डिज़ाइन

पेरिस्टाल्टिक होज़ तकनीक ने उद्योगों में तरल पदार्थों के परिवहन और पंपिंग के तरीके में क्रांतिकारी बदलाव ला दिया है। यह नवोन्मेषी तकनीक कई लाभ प्रदान करती है, जिनमें बेहतर कार्यक्षमता और डिज़ाइन शामिल हैं, जिसके कारण यह फार्मास्युटिकल, खाद्य और पेय पदार्थ, अपशिष्ट जल उपचार और कई अन्य क्षेत्रों में एक आवश्यक उपकरण बन गई है। इस लेख में, हम पेरिस्टाल्टिक होज़ तकनीक के उपयोग के लाभों पर विस्तार से चर्चा करेंगे, विशेष रूप से इसकी कार्यक्षमता और डिज़ाइन पर ध्यान केंद्रित करेंगे।

कार्यक्षमता के लिहाज़ से, पेरिस्टाल्टिक होज़ तकनीक तरल पदार्थों को एक बिंदु से दूसरे बिंदु तक सटीक और कुशलतापूर्वक स्थानांतरित करने की अपनी क्षमता में बेजोड़ है। पेरिस्टाल्टिक पंपों की अनूठी कार्यप्रणाली, जो एक घूर्णनशील रोलर का उपयोग करके तरल पदार्थ को एक लचीली नली के माध्यम से संपीड़ित और स्थानांतरित करती है, संदूषण या बैकफ़्लो के किसी भी जोखिम के बिना तरल पदार्थ का निरंतर और सहज प्रवाह सुनिश्चित करती है। यह सटीक और स्थिर पंपिंग क्रिया पेरिस्टाल्टिक होज़ तकनीक को संवेदनशील अनुप्रयोगों के लिए आदर्श बनाती है, जहाँ तरल पदार्थ की शुद्धता और अखंडता को बनाए रखना सर्वोपरि है।

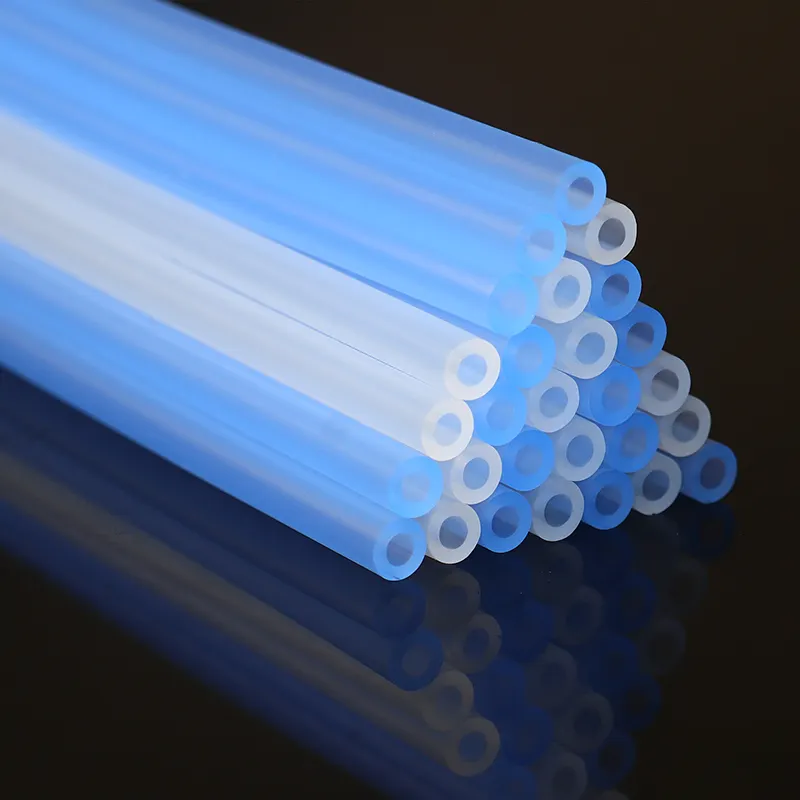

इसके अलावा, पेरिस्टाल्टिक होज़ तकनीक का डिज़ाइन विभिन्न औद्योगिक अनुप्रयोगों के लिए उपयुक्त है। पेरिस्टाल्टिक पंपों में उपयोग होने वाली लचीली ट्यूबिंग सिलिकॉन, ईपीडीएम और प्राकृतिक रबर जैसी विभिन्न सामग्रियों में उपलब्ध है, जिससे यह विभिन्न प्रकार के तरल पदार्थों और रसायनों के साथ अनुकूल हो जाती है। यह बहुमुखी प्रतिभा पेरिस्टाल्टिक होज़ तकनीक को आक्रामक या अपघर्षक तरल पदार्थों से निपटने वाले उद्योगों के लिए एक विश्वसनीय विकल्प बनाती है, क्योंकि ट्यूबिंग को अनुप्रयोग की विशिष्ट आवश्यकताओं के अनुरूप चुना जा सकता है।

इसके अलावा, पेरिस्टाल्टिक पंपों का सरल और कॉम्पैक्ट डिज़ाइन उन्हें स्थापित करना और संचालित करना आसान बनाता है, जिससे न्यूनतम रखरखाव और डाउनटाइम की आवश्यकता होती है। पेरिस्टाल्टिक होज़ तकनीक में सील, वाल्व और डायाफ्राम की अनुपस्थिति नियमित प्रतिस्थापन की आवश्यकता को समाप्त करती है और रिसाव या फैलाव के जोखिम को कम करती है, जिसके परिणामस्वरूप व्यवसायों के लिए लागत बचत और बढ़ी हुई दक्षता प्राप्त होती है।

अपनी व्यावहारिक कार्यक्षमता और डिज़ाइन के अलावा, पेरिस्टाल्टिक होज़ तकनीक कई अन्य लाभ भी प्रदान करती है, जो इसे तरल पदार्थों के प्रबंधन के लिए एक पसंदीदा विकल्प बनाती है। प्रमुख लाभों में से एक पेरिस्टाल्टिक पंपों की कोमल पंपिंग क्रिया है, जो विशेष रूप से सेल कल्चर और फार्मास्युटिकल उत्पादों जैसे कतरन-संवेदनशील तरल पदार्थों के लिए लाभकारी है। होज़ की कोमल निचोड़ने की क्रिया तरल पदार्थ के झाग बनने और खराब होने से बचाती है, जिससे उत्पाद की गुणवत्ता और अखंडता सुनिश्चित होती है।

इसके अलावा, पेरिस्टाल्टिक होज़ तकनीक स्वाभाविक रूप से स्वच्छ और स्वास्थ्यकर है, क्योंकि तरल पदार्थ केवल ट्यूब के अंदरूनी भाग के संपर्क में आता है, जिससे पंप से संदूषण का खतरा समाप्त हो जाता है। यह विशेषता खाद्य और पेय पदार्थ, दवा और जैव प्रौद्योगिकी जैसे उद्योगों में विशेष रूप से महत्वपूर्ण है, जहाँ रोगाणु-मुक्त वातावरण बनाए रखना आवश्यक है।

निष्कर्षतः, पेरिस्टाल्टिक होज़ तकनीक की कार्यक्षमता और डिज़ाइन इसे तरल पदार्थों के संचालन और पंपिंग के लिए एक अत्यंत प्रभावी और बहुमुखी समाधान बनाती है। इसकी सटीक और सौम्य पंपिंग क्रिया, साथ ही इसके विश्वसनीय और कम रखरखाव वाले डिज़ाइन ने पेरिस्टाल्टिक होज़ तकनीक को विभिन्न उद्योगों के लिए एक अनिवार्य उपकरण बना दिया है। चाहे वह दवा निर्माण हो, खाद्य प्रसंस्करण हो या अपशिष्ट जल उपचार, पेरिस्टाल्टिक होज़ तकनीक अद्वितीय लाभ प्रदान करती रहती है, जिससे यह तरल पदार्थों के संचालन के लिए पसंदीदा विकल्प बन जाती है।

औद्योगिक अनुप्रयोगों में पेरिस्टाल्टिक होज़ तकनीक के उपयोग के लाभ

पेरिस्टाल्टिक होज़ तकनीक विभिन्न औद्योगिक अनुप्रयोगों में उपयोग की जाने वाली एक अत्यंत कुशल और विश्वसनीय विधि है। यह नवोन्मेषी तकनीक पारंपरिक होज़ प्रणालियों की तुलना में कई लाभ प्रदान करती है, जिससे यह फार्मास्युटिकल, खाद्य एवं पेय पदार्थ और अपशिष्ट जल उपचार जैसे उद्योगों के लिए एक आदर्श विकल्प बन जाती है। इस लेख में, हम औद्योगिक अनुप्रयोगों में पेरिस्टाल्टिक होज़ तकनीक के उपयोग के अनेक लाभों का पता लगाएंगे।

पेरिस्टाल्टिक होज़ तकनीक का एक प्रमुख लाभ यह है कि यह विभिन्न प्रकार के तरल पदार्थों और पदार्थों को आसानी से संभाल सकती है। होज़ की लचीली प्रकृति के कारण यह विभिन्न सामग्रियों को संदूषण के खतरे के बिना समायोजित कर सकती है। यह उन उद्योगों में विशेष रूप से महत्वपूर्ण है जहां तरल पदार्थों की शुद्धता बनाए रखना अत्यंत आवश्यक है, जैसे कि फार्मास्युटिकल और खाद्य प्रसंस्करण संयंत्र। पेरिस्टाल्टिक होज़ संक्षारक और अपघर्षक दोनों प्रकार के तरल पदार्थों को संभालने के लिए डिज़ाइन किए गए हैं, जिससे वे विभिन्न औद्योगिक अनुप्रयोगों के लिए एक बहुमुखी विकल्प बन जाते हैं।

पेरिस्टाल्टिक होज़ तकनीक का एक और प्रमुख लाभ इसकी सटीक और स्थिर प्रवाह दर प्रदान करने की क्षमता है। होज़ की डिज़ाइन तरल पदार्थ को किसी भी आंतरिक घटक के संपर्क में आने से रोकती है, जिससे अवरोध या प्रवाह में रुकावट का खतरा कम हो जाता है। प्रवाह दर पर यह सटीक नियंत्रण उन उद्योगों में आवश्यक है जहाँ तरल पदार्थों की मात्रा और मापन महत्वपूर्ण होते हैं, जैसे कि रासायनिक उत्पादन और जल उपचार संयंत्र। पेरिस्टाल्टिक होज़ तकनीक से औद्योगिक प्रक्रियाएँ अधिक कुशल और विश्वसनीय बन सकती हैं, जिसके परिणामस्वरूप समग्र उत्पादन गुणवत्ता में सुधार होता है।

इसके अतिरिक्त, पेरिस्टाल्टिक होज़ तकनीक आसान रखरखाव और न्यूनतम डाउनटाइम प्रदान करती है। होज़ ही एकमात्र घटक है जो तरल पदार्थ के संपर्क में आता है, इसलिए केवल इसी भाग को नियमित रूप से बदलने की आवश्यकता होती है। इससे रखरखाव सरल हो जाता है और अन्य घटकों की बार-बार सफाई और स्टरलाइज़ेशन की आवश्यकता कम हो जाती है, जिससे समय और श्रम लागत दोनों की बचत होती है। परिणामस्वरूप, औद्योगिक कार्य न्यूनतम व्यवधानों के साथ सुचारू रूप से चल सकते हैं, जिससे समग्र उत्पादकता में सुधार होता है।

इसके अलावा, पेरिस्टाल्टिक होज़ तकनीक तरल पदार्थों को कोमल तरीके से संभालने की अपनी क्षमता के लिए जानी जाती है। होज़ की सिकुड़ने वाली क्रिया कतरन बलों और वायु अवरोधन को रोकती है, जो नाजुक तरल पदार्थों के लिए हानिकारक हो सकते हैं। यह उन उद्योगों में विशेष रूप से फायदेमंद है जहां जैविक नमूनों या महंगे रसायनों जैसे संवेदनशील पदार्थों का स्थानांतरण किया जाता है। तरल पदार्थों को कोमल तरीके से संभालने से उनकी अखंडता और गुणवत्ता बनी रहती है, जिससे औद्योगिक प्रक्रियाओं में लगातार और विश्वसनीय परिणाम सुनिश्चित होते हैं।

निष्कर्षतः, औद्योगिक अनुप्रयोगों में पेरिस्टाल्टिक होज़ तकनीक के उपयोग के अनेक और महत्वपूर्ण लाभ हैं। विभिन्न प्रकार के तरल पदार्थों को संभालने की इसकी क्षमता, सटीक प्रवाह दर प्रदान करना, आसान रखरखाव और तरल पदार्थों को सौम्य तरीके से संभालना इसे विभिन्न उद्योगों के लिए एक आदर्श विकल्प बनाता है। अपनी बहुमुखी प्रतिभा, विश्वसनीयता और दक्षता के कारण, पेरिस्टाल्टिक होज़ तकनीक औद्योगिक प्रक्रियाओं के समग्र प्रदर्शन को बेहतर बनाने में एक महत्वपूर्ण भूमिका निभाती है। जैसे-जैसे उद्योग विकसित हो रहे हैं और अधिक उन्नत तरल पदार्थ प्रबंधन समाधानों की मांग कर रहे हैं, पेरिस्टाल्टिक होज़ तकनीक निश्चित रूप से इन आवश्यकताओं को पूरा करने में महत्वपूर्ण भूमिका निभाएगी।

पेरिस्टाल्टिक होज़ तकनीक के उपयोग के पर्यावरणीय और सुरक्षा संबंधी लाभ

पेरिस्टाल्टिक होज़ तकनीक एक क्रांतिकारी नवाचार है जो उद्योगों में द्रव स्थानांतरण और पंपिंग प्रणालियों के संचालन के तरीके को बदल रहा है। यह लेख पेरिस्टाल्टिक होज़ तकनीक के पर्यावरणीय और सुरक्षा संबंधी लाभों का विश्लेषण करेगा, पारंपरिक पंपिंग विधियों की तुलना में इसके फायदों और विभिन्न उद्योगों में संचालन को बेहतर बनाने की इसकी क्षमता पर प्रकाश डालेगा।

पेरिस्टाल्टिक होज़ प्रौद्योगिकी के पर्यावरणीय लाभ

पेरिस्टाल्टिक होज़ तकनीक का एक प्रमुख पर्यावरणीय लाभ तरल रिसाव और फैलाव के जोखिम को कम करने की इसकी क्षमता है। पारंपरिक पंपिंग प्रणालियों के विपरीत, जो अक्सर सील और वाल्व पर निर्भर करती हैं जो समय के साथ खराब हो सकती हैं, पेरिस्टाल्टिक होज़ में एक सरल, बंद-लूप डिज़ाइन होता है जो रिसाव और फैलाव के जोखिम को कम करता है। इससे कंपनियों को मिट्टी और जल स्रोतों के प्रदूषण को रोककर, साथ ही सफाई कार्यों और नियामक जुर्माने की आवश्यकता को कम करके अपने पर्यावरणीय प्रभाव को कम करने में मदद मिल सकती है।

इसके अलावा, पेरिस्टाल्टिक होज़ तकनीक पारंपरिक पंपिंग विधियों की तुलना में अधिक ऊर्जा-कुशल है। होज़ की डिज़ाइन तरल प्रवाह पर सटीक नियंत्रण की अनुमति देती है, जिससे सिस्टम के माध्यम से तरल पदार्थों को पंप करने के लिए आवश्यक ऊर्जा की मात्रा कम हो जाती है। इससे न केवल कंपनियों को अपने कार्बन फुटप्रिंट को कम करने में मदद मिलती है, बल्कि परिचालन लागत भी कम होती है और समग्र पर्यावरणीय स्थिरता में सुधार होता है।

पेरिस्टाल्टिक होज़ तकनीक के सुरक्षा संबंधी लाभ

सुरक्षा की दृष्टि से, पेरिस्टाल्टिक होज़ तकनीक पारंपरिक पंपिंग प्रणालियों की तुलना में महत्वपूर्ण लाभ प्रदान करती है। होज़ों का बंद लूप डिज़ाइन खतरनाक रसायनों और तरल पदार्थों के संपर्क में आने के जोखिम को कम करता है, जिससे कार्यस्थल पर दुर्घटनाओं और चोटों की संभावना कम हो जाती है। यह उन उद्योगों में विशेष रूप से महत्वपूर्ण है जहां श्रमिक नियमित रूप से खतरनाक पदार्थों के संपर्क में आते हैं, जैसे कि दवा निर्माण और रासायनिक प्रसंस्करण।

इसके अलावा, पेरिस्टाल्टिक होज़ को घर्षणकारी और संक्षारक पदार्थों सहित विभिन्न प्रकार के तरल पदार्थों को संभालने के लिए डिज़ाइन किया गया है, और इसके लिए अतिरिक्त रोकथाम उपायों की आवश्यकता नहीं होती है। इससे विशेष संचालन प्रक्रियाओं और उपकरणों की आवश्यकता कम हो जाती है, जिससे कार्य संचालन सरल हो जाता है और कार्यस्थल पर समग्र सुरक्षा में सुधार होता है।

पेरिस्टाल्टिक होज़ प्रौद्योगिकी के व्यावहारिक अनुप्रयोग

पेरिस्टाल्टिक होज़ तकनीक का उपयोग फार्मास्यूटिकल्स, खाद्य एवं पेय पदार्थ, खनन, जल उपचार और रासायनिक प्रसंस्करण सहित विभिन्न उद्योगों में व्यापक रूप से होता है। उदाहरण के लिए, फार्मास्यूटिकल उद्योग में, पेरिस्टाल्टिक होज़ का उपयोग संवेदनशील और मूल्यवान तरल पदार्थों, जैसे सक्रिय फार्मास्युटिकल सामग्री (एपीआई), को संदूषण के न्यूनतम जोखिम के साथ स्थानांतरित करने के लिए किया जाता है। इससे कंपनियों को उत्पाद की गुणवत्ता और सुरक्षा के उच्च मानकों को बनाए रखने में मदद मिलती है, साथ ही महंगे उत्पाद रिकॉल के जोखिम को भी कम किया जा सकता है।

खाद्य एवं पेय उद्योग में, पेरिस्टाल्टिक होज़ तकनीक का उपयोग सामग्रियों की सटीक मात्रा मापने और मिश्रण करने के साथ-साथ उन नाज़ुक तरल पदार्थों को संभालने के लिए किया जाता है जिन्हें कोमल पंपिंग क्रियाओं की आवश्यकता होती है। इससे उत्पाद की गुणवत्ता में निरंतरता सुनिश्चित होती है और उत्पाद के खराब होने का जोखिम कम होता है, जिससे खाद्य सुरक्षा और ग्राहक संतुष्टि बढ़ती है।

निष्कर्षतः, पेरिस्टाल्टिक होज़ तकनीक पारंपरिक पंपिंग विधियों की तुलना में पर्यावरण और सुरक्षा के लिहाज़ से महत्वपूर्ण लाभ प्रदान करती है, जिससे यह उन कंपनियों के लिए एक आकर्षक विकल्प बन जाती है जो पर्यावरण पर अपने प्रभाव को कम करते हुए अपने संचालन में सुधार करना चाहती हैं। ऊर्जा-कुशल डिज़ाइन, रिसाव और फैलाव के न्यूनतम जोखिम और उन्नत सुरक्षा सुविधाओं के साथ, पेरिस्टाल्टिक होज़ तकनीक उद्योगों में तरल स्थानांतरण और पंपिंग प्रणालियों को संभालने के तरीके में क्रांतिकारी बदलाव लाने के लिए तैयार है।

पेरिस्टाल्टिक होज़ प्रौद्योगिकी का भविष्य और विभिन्न उद्योगों में इसके संभावित अनुप्रयोग

पेरिस्टाल्टिक होज़ तकनीक ने अपने अनूठे डिज़ाइन और कार्यों के कारण विभिन्न उद्योगों में क्रांतिकारी बदलाव लाए हैं। यह लेख पेरिस्टाल्टिक होज़ तकनीक के भविष्य और विभिन्न उद्योगों में इसके संभावित अनुप्रयोगों पर विस्तार से चर्चा करेगा।

पेरिस्टाल्टिक होज़ तकनीक क्या है?

पेरिस्टाल्टिक होज़ तकनीक एक प्रकार का धनात्मक विस्थापन पंप है जिसका उपयोग विभिन्न प्रकार के तरल पदार्थों को पंप करने के लिए किया जाता है। यह तकनीक पेरिस्टालसिस के सिद्धांत पर काम करती है, जिसमें एक लचीली नली को रोटर द्वारा उसकी लंबाई के साथ दबाया जाता है, जिससे नली के अंदर तरल पदार्थ धकेला जाता है। पेरिस्टाल्टिक होज़ तकनीक की कार्यप्रणाली पारंपरिक पंपों से इस मायने में भिन्न है कि इसमें किसी सील, वाल्व या अन्य ऐसे पुर्जों की आवश्यकता नहीं होती जो तरल पदार्थ के सीधे संपर्क में आते हों, जिससे यह स्वच्छतापूर्ण और कम रखरखाव वाला विकल्प बन जाता है।

पेरिस्टाल्टिक होज़ प्रौद्योगिकी का भविष्य:

पेरिस्टाल्टिक होज़ तकनीक के क्षेत्र में निरंतर प्रगति और नवाचारों के साथ इसका भविष्य उज्ज्वल दिख रहा है। तकनीक में सुधार के साथ, पेरिस्टाल्टिक होज़ अधिक कुशल, टिकाऊ और बहुमुखी बन रहे हैं, जिससे विभिन्न उद्योगों में इसके अनेक संभावित अनुप्रयोग खुल रहे हैं।

विभिन्न उद्योगों में संभावित अनुप्रयोग:

1. चिकित्सा एवं औषधि उद्योग:

पेरिस्टाल्टिक होज़ तकनीक ने तरल पदार्थ के विश्वसनीय और सटीक स्थानांतरण के तरीके के रूप में चिकित्सा और फार्मास्युटिकल उद्योग में पहले ही महत्वपूर्ण योगदान दिया है। यह तकनीक दवा वितरण प्रणालियों, डायलिसिस मशीनों और अन्य चिकित्सा उपकरणों में व्यापक रूप से उपयोग की जाती है, जहाँ सटीक और रोगाणुरहित तरल स्थानांतरण अत्यंत महत्वपूर्ण है।

2. खाद्य एवं पेय उद्योग:

पेरिस्टाल्टिक होज़ तकनीक अपने स्वच्छ डिज़ाइन और नाज़ुक तरल पदार्थों को संभालने की क्षमता के कारण खाद्य और पेय उद्योग के लिए काफी फायदेमंद साबित हो सकती है। इस तकनीक का उपयोग आमतौर पर खाद्य और पेय पदार्थों के उत्पादन प्रक्रियाओं में सामग्री, स्वाद और अन्य तरल पदार्थों को स्थानांतरित करने के लिए किया जाता है।

3. रासायनिक एवं विनिर्माण उद्योग:

पेरिस्टाल्टिक होज़ तकनीक का उपयोग रासायनिक और विनिर्माण उद्योगों में संक्षारक, अपघर्षक या संवेदनशील तरल पदार्थों के स्थानांतरण के लिए भी किया जा सकता है। रसायनों की एक विस्तृत श्रृंखला को संभालने और प्रदूषण-मुक्त वातावरण बनाए रखने की क्षमता के कारण, पेरिस्टाल्टिक होज़ विभिन्न औद्योगिक प्रक्रियाओं के लिए एक आदर्श विकल्प हैं।

4. जल एवं अपशिष्ट प्रबंधन:

जल एवं अपशिष्ट प्रबंधन के क्षेत्र में, पेरिस्टाल्टिक होज़ तकनीक का उपयोग जल उपचार संयंत्रों, अपशिष्ट जल प्रबंधन सुविधाओं और अन्य संबंधित अनुप्रयोगों में विभिन्न रसायनों और तरल पदार्थों की खुराक देने और स्थानांतरण के लिए किया जा सकता है। पेरिस्टाल्टिक होज़ की कोमल पंपिंग क्रिया उन्हें अपरूपण-संवेदनशील तरल पदार्थों को संभालने के लिए भी उपयुक्त बनाती है।

पेरिस्टाल्टिक होज़ तकनीक के निरंतर विकास और सुधार के साथ, विभिन्न उद्योगों में इसके संभावित अनुप्रयोगों का दायरा और भी बढ़ेगा। पेरिस्टाल्टिक होज़ तकनीक के कई लाभ हैं, जैसे कि इसका स्वच्छ डिज़ाइन, सटीक द्रव स्थानांतरण और बहुमुखी प्रतिभा, जो इसे कई औद्योगिक अनुप्रयोगों के लिए एक आकर्षक विकल्प बनाते हैं। निरंतर अनुसंधान और प्रगति के साथ, पेरिस्टाल्टिक होज़ तकनीक उद्योगों की एक विस्तृत श्रृंखला में द्रव स्थानांतरण प्रक्रियाओं में क्रांतिकारी बदलाव लाने के लिए तैयार है।

निष्कर्ष

निष्कर्षतः, पेरिस्टाल्टिक होज़ तकनीक के लाभ वास्तव में प्रभावशाली हैं। विभिन्न प्रकार के तरल पदार्थों और सामग्रियों को संभालने की क्षमता, कम रखरखाव की आवश्यकता और लंबी सेवा अवधि से स्पष्ट है कि यह तकनीक विभिन्न उद्योगों के लिए अनेक लाभ प्रदान करती है। उद्योग में 12 वर्षों के अनुभव वाली कंपनी के रूप में, हमने पेरिस्टाल्टिक होज़ तकनीक के संचालन, दक्षता और समग्र प्रदर्शन पर पड़ने वाले सकारात्मक प्रभाव को प्रत्यक्ष रूप से देखा है। इसकी विश्वसनीयता और बहुमुखी प्रतिभा के कारण, यह आश्चर्य की बात नहीं है कि अधिक से अधिक कंपनियां अपनी तरल पदार्थ प्रबंधन आवश्यकताओं को पूरा करने के लिए पेरिस्टाल्टिक होज़ तकनीक की ओर रुख कर रही हैं। यदि आप अपने संचालन को अनुकूलित करना और अपने लाभ को बढ़ाना चाहते हैं, तो अपनी प्रक्रियाओं में पेरिस्टाल्टिक होज़ तकनीक को शामिल करने पर विचार करें।

-

6. निष्कर्ष